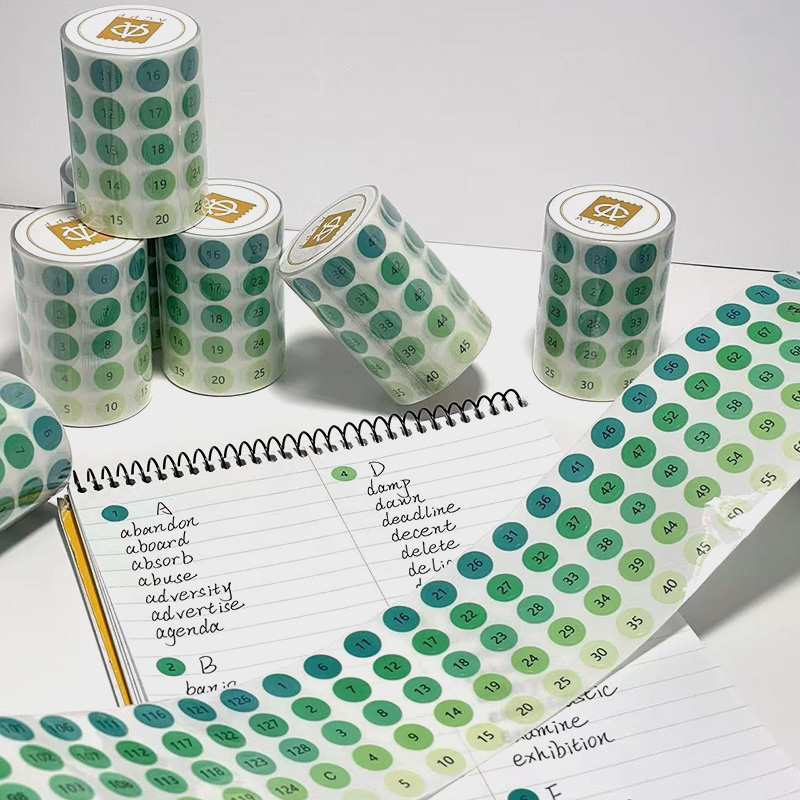

Comprehensive Guarante To Meet Your Diverse Needs

High-definition printing: bright colors and clear patterns

High-quality and durable: wear-resistant and stretch-resistant

2025-05-22 14:28:59

Digital Printed BOPP (Biaxially Oriented Polypropylene) Labels are high-quality, durable labels produced using digital printing technology on BOPP film substrates. These labels combine the versatility of digital printing with the superior physical and chemical properties of BOPP, making them ideal for various industries requiring premium labeling solutions.

Exceptional Print Quality: Digital printing achieves resolutions up to 1200 dpi with a color gamut covering 95% of the Pantone Matching System (PMS), enabling photorealistic graphics and sharp text.

Water and Chemical Resistance: BOPP film has a water absorption rate of <0.1% (ASTM D570) and withstands exposure to acids, alkalis (pH 1-14), and most solvents without degradation.

Durability: With tensile strength of 150-300 MPa (machine direction) and 200-400 MPa (transverse direction), these labels maintain integrity in harsh environments.

Temperature Stability: Stable performance across -40°C to 120°C with heat deflection temperature of 110°C (ASTM D648), suitable for frozen food and hot-fill applications.

UV Resistance: Special coatings provide 5+ years outdoor durability with <10% color fade (ASTM D4329 accelerated weathering testing).

Flexibility: Elastic modulus of 1.5-2.5 GPa allows conformability to curved surfaces down to 5mm radius without cracking.

Adhesion Performance: Peel adhesion values of 10-15 N/25mm (FINAT FTM 1) ensure secure bonding to various substrates.

Digital Printed BOPP Labels serve diverse industries with their combination of durability and print quality:

Bottled Beverages: Withstand condensation and refrigeration (2-4°C) while maintaining adhesion and legibility

Frozen Food Packaging: Remain flexible and adherent at -18°C without cracking or delamination

Canned Goods: Resist steam sterilization processes at 121°C for 20-30 minutes

Oil Containers: Impermeable to grease and oil penetration (oil resistance rating >8 according to ASTM D722)

Medicine Bottles: Maintain legibility after repeated sterilization (ethylene oxide, gamma radiation)

Medical Devices: Comply with ISO 10993-5 cytotoxicity requirements for skin contact

Laboratory Specimens: Resist common laboratory chemicals including 70% ethanol and isopropanol

Automotive Fluids: Withstand exposure to motor oils, brake fluids, and antifreeze

Cleaning Products: Resist bleach solutions up to 5% sodium hypochlorite

Agricultural Chemicals: Maintain integrity when exposed to pesticides and fertilizers

Cosmetics: Provide high-gloss finishes (85+ gloss units at 60°) for premium appearance

Electronics: Carry UL/CSA recognition for use on appliance surfaces

Promotional Items: Enable short-run, variable data printing for personalized marketing

Proper handling and storage ensure optimal performance of Digital Printed BOPP Labels:

Maintain temperature between 15-25°C with relative humidity at 40-60% RH

Store rolls vertically on cores with minimum 75mm diameter to prevent deformation

Protect from direct sunlight (UV exposure <5 kLux hours before application)

Keep in original packaging until use to prevent dust accumulation

Surface energy of substrate should exceed 38 dynes/cm (measured by dyne pens)

Apply at temperatures between 10-35°C for optimal adhesive performance

Use application pressure of 40-60 psi for proper bonding without distortion

Allow 24-72 hours for adhesive to reach full bond strength (depending on temperature)

For surface cleaning, use mild detergents (pH 6-8) with soft cloths (abrasion resistance >1,000 cycles - ASTM D4060)

Avoid abrasive cleaners with particle size >50μm that may scratch the surface

For disinfecting, use alcohol solutions (70% ethanol or isopropanol) with contact time <5 minutes

Do not use ketone-based solvents (acetone, MEK) which may affect the printed surface

Printed labels maintain legibility for 2-5 years indoors (lightfastness rating 7-8 on Blue Wool Scale)

For archival purposes, store labeled items away from heat sources (>50°C accelerates aging)

Consider protective laminates (2-5μm) for extended outdoor exposure (>3 years)

2/F, No. 23, Um Yuan Xin Road, Wentang Community, Dongcheng Street, Dongguan City, Guangdong Province, China

+86 137-1733-9986 +86-0769-22299566