Comprehensive Guarante To Meet Your Diverse Needs

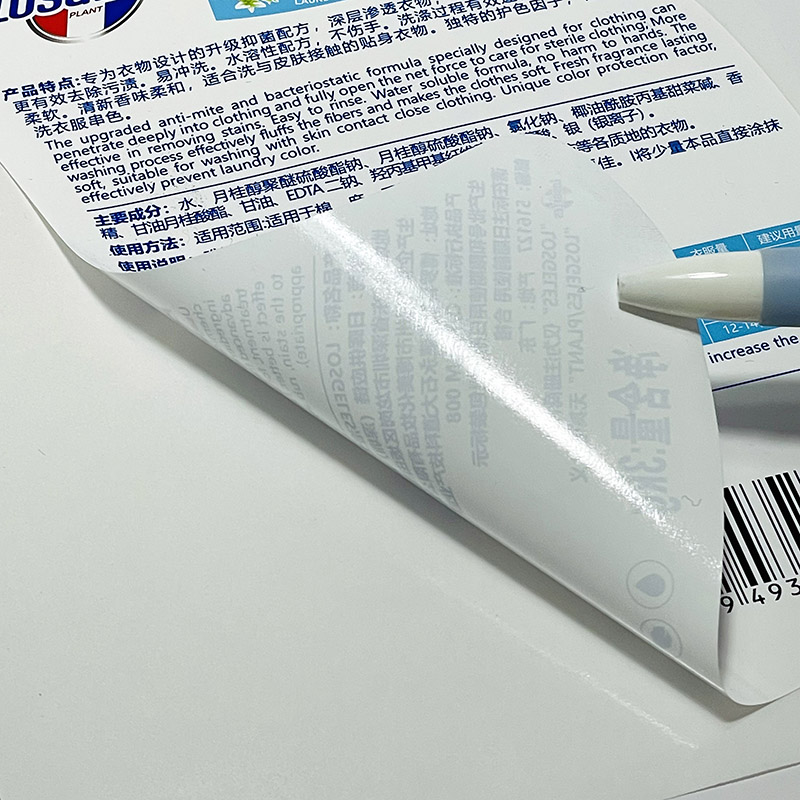

High-definition printing: bright colors and clear patterns

High-quality and durable: wear-resistant and stretch-resistant

2025-06-20 16:10:55

Custom die-cut self-Adhesive labels are precision-cut Labels manufactured to specific shapes and sizes using specialized die-cutting equipment. These labels feature a pressure-sensitive adhesive backing that activates upon application, requiring no additional moisture or heat. The die-cutting process allows for ±0.2mm dimensional tolerance, enabling complex shapes beyond standard rectangles or circles. The adhesive layer typically has a peel strength ranging from 20-80 N/25mm (depending on substrate), while the face stock material maintains tear resistance between 50-400 mN (measured by Elmendorf method). Modern production utilizes computer-controlled rotary die-cutting achieving speeds up to 300 meters/minute with registration accuracy of ±0.1mm.

Material Composition: Typically consists of face stock (paper/PP/PE/PET), adhesive (rubber/acrylic/silicone), and liner (glassine/kraft) with caliper thickness 50-250μm

Adhesive Performance: Initial tack values range 5-25 N/25mm (FINAT FTM 9), with ultimate adhesion reaching 15-50 N/25mm after 24h dwell time

Environmental Resistance: Temperature range from -40°C to +150°C for specialty adhesives, with UV resistance up to 500+ hours QUV testing

Print Compatibility: Supports flexo (120-175 LPI), digital (2400 dpi), and screen printing (55-85 threads/cm) with color gamut coverage exceeding 90% Pantone

Die-Cut Precision: Minimum radius of 0.5mm achievable with hardened steel rule dies, kiss-cut depth control within ±10μm

In manufacturing environments, these labels withstand IP65-IP68 conditions for equipment identification. Chemical-resistant variants maintain legibility after 30+ solvent wipe cycles (ASTM D5402). Barcode labels achieve ANSI Grade A/B scanability even after abrasion testing (1,000+ Taber cycles).

High-gloss facestocks achieve 90+ brightness with 2H-3H pencil hardness for scratch resistance. Specialty coatings enable cold foil stamping with ΔE<2 color consistency across production runs.

Autoclave-compatible labels endure 134°C sterilization cycles while maintaining BS5609 certification for marine immersion. Pharmaceutical labels incorporate tamper-evident features with <25g initiation force.

Direct-food-contact materials comply with FDA 21 CFR 175.105 and EU 10/2011, withstanding -18°C freezer to 121°C retort conditions. Ice-water resistant adhesives maintain bond strength above 10 N/25mm after 24h immersion.

ESD-safe labels exhibit surface resistance 10^6-10^9 ohms/sq (ANSI/ESD S541), with UL-recognized variants for 94V-0 flammability rating.

Optimal storage maintains 23±2°C temperature and 50±5% RH. Rolls should be stored vertically to prevent >3% edge distortion. Shelf life ranges 6-24 months depending on adhesive chemistry.

Surface energy should exceed 38 dynes/cm (measured by dyne pens). Application pressure of 40-60 psi ensures proper wet-out, with 24h cure time before environmental exposure.

Isopropyl alcohol (70% concentration) effectively removes adhesive residue without damaging most substrates. For sensitive surfaces, citrus-based cleaners with pH 5-8 are recommended.

Regular inspection should verify >90% adhesion (ASTM D3359) and ΔE<3 color shift (ISO 105-A02). UV-exposed labels require replacement when gloss retention falls below 60% (ASTM D2457).

2/F, No. 23, Um Yuan Xin Road, Wentang Community, Dongcheng Street, Dongguan City, Guangdong Province, China

+86 137-1733-9986 +86-0769-22299566