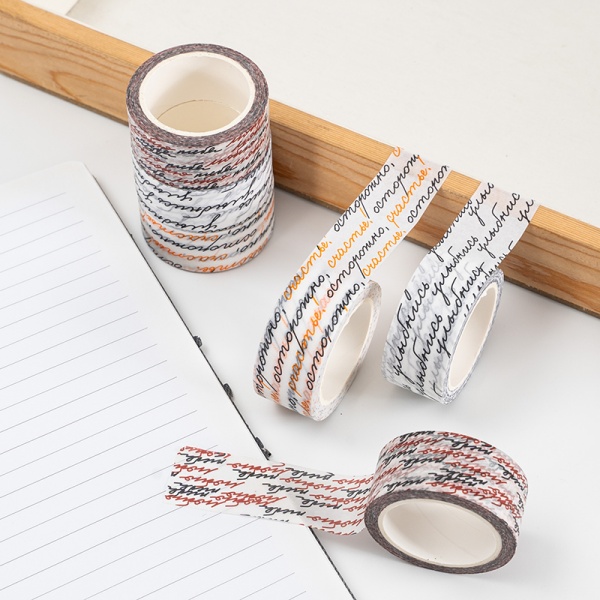

Comprehensive Guarante To Meet Your Diverse Needs

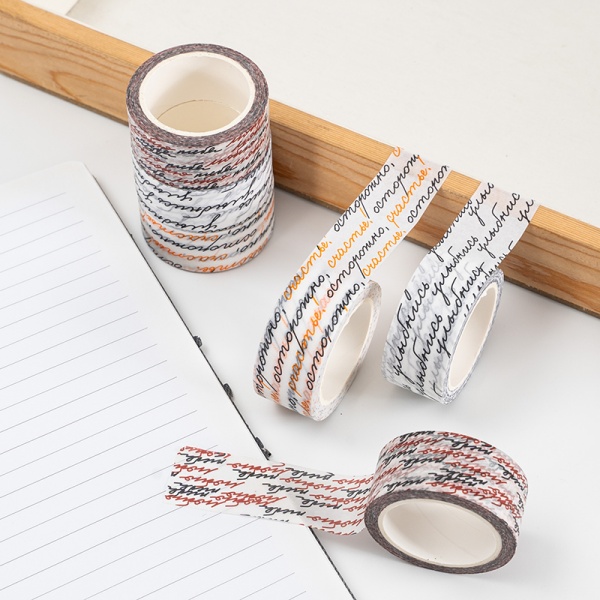

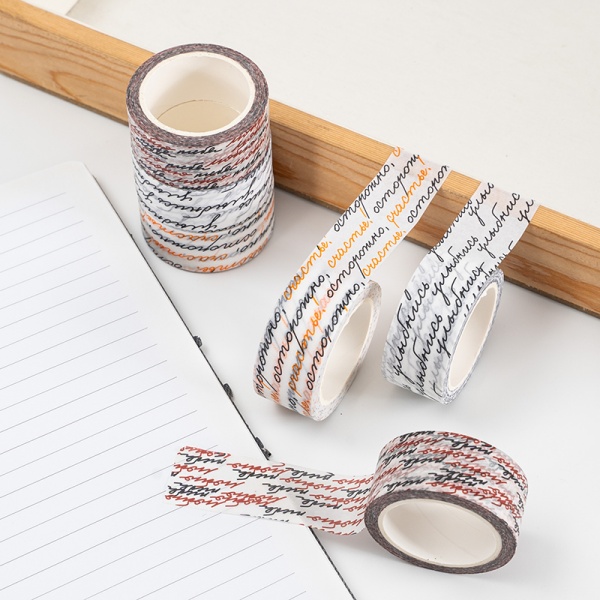

High-definition printing: bright colors and clear patterns

High-quality and durable: wear-resistant and stretch-resistant

Looking for Washi Tape wholesale options for your business? Dongguan Chengdong Printing & Packaging Co., Ltd. offers a wide range of custom washi tape solutions designed for bulk orders, ensuring you get the best value for your money. Whether you need branded tape for packaging or decorative tape for home decor, we have the perfect solution.

Decorative Tape for Crafts is a core material in the field of handicrafts that combines functionality and artistry. With its unique material characteristics, rich design language, and wide range of applicable scenarios, it has become a "universal accessory" for modern handicrafts, DIY decoration, and creative design.

1、 Core Features and Technical Parameters: Fine Analysis from Material to Process

Material diversity: differentiated applications of paper, PET, and metal substrates

Washi Tape: Based on traditional Japanese washi paper, the thickness is usually 0.05-0.1mm and the weight is 60-80g/m ². Its low viscosity pressure-sensitive adhesive (peel strength ≤ 0.2N/25mm) can achieve seamless tearing and pasting. According to SGS testing, it can be repeatedly pasted more than 50 times without leaving any residue. For example, Stamprints brand uses FSC certified washi paper with a fiber density of 1200 mesh/cm ², ensuring a printing color saturation of over 92%.

PET tape: made of polyethylene terephthalate as the substrate, with a thickness of 0.08-0.15mm, a tensile strength of 120MPa (ASTM D882 standard), a temperature range of -20 ℃ to 80 ℃, suitable for scenarios that require long-term fixation. The metallic texture PET tape launched by JWshufel brand achieves 98% glossiness through vacuum coating process, with a surface hardness of 3H (pencil hardness test).

Metal tape: made of aluminum foil or copper foil as the substrate, with a thickness of 0.03-0.06mm and a reflectivity of ≥ 85% (DIN 5036 standard), commonly used for holiday decoration or high-end gift packaging. The metal tape series from BLICK Art Materials achieves 12 colors including 24K gold and rose gold through anodizing treatment, and its corrosion resistance meets the 48 hour salt spray test of ISO 9227 standard.

Adhesive control: gradient design from temporary fixation to permanent bonding

Low viscosity tape: The initial adhesive strength of the paper tape is 8-12N/25mm (FINAT FTM1 standard), suitable for scenarios such as notebook decoration and photo walls that require frequent adjustments. Experimental data shows that its adhesion time on smooth surfaces (such as glass and plastic) can reach 72 hours, while on rough surfaces (such as wood and fabric) it can be shortened to 24 hours.

Medium adhesive tape: The initial adhesive strength of PET tape is 15-20N/25mm, suitable for scenarios requiring medium strength such as gift packaging and card making. Its adhesion can last for 30 days under standard conditions (23 ℃/50% RH), and the residual rate after peeling is ≤ 0.5%.

High viscosity tape: The initial adhesion force of metal tape is ≥ 25N/25mm, suitable for outdoor decoration or scenes that require long-term fixation. Through the formulation of cross-linked acrylic adhesive, its weather resistance meets the 1000 hour UV aging test of ASTM G154 standard.

Printing Technology: Visual Upgrade from Flat to Stereoscopic

High precision color matching printing: using 6-color UV printing technology, with a color gamut coverage of 95% sRGB and a resolution of 1200dpi, it can achieve complex effects such as gradients and metallic textures. For example, AUHomi brand's vintage patterned tape reproduces the delicate brushstrokes of a 19th-century European botanical catalog through spot color printing.

Special process applications: including hot pressing (temperature 120-150 ℃), cold pressing laser (accuracy ± 0.05mm), relief embossing (depth 0.02-0.05mm), etc. Stamprints' "Starry Sky Series" tape achieves a 0.01mm level grating effect within a thickness of 0.1mm through micro nano structure imprinting technology, presenting dynamic nebula patterns when the viewing angle changes.

2、 Application scenario: Full coverage from personal creation to commercial design

Handmade creation field

Handbooks and diary decorations: The tearability of paper tape makes it a "color library" for bookkeeping enthusiasts. Data shows that the global accounting market consumes over 500 million rolls of decorative tape annually, of which 70% is used for structured decorations such as borders and title frames.

Paper art and fabric modification: The water resistance (IPX3 level) of PET tape makes it the preferred material for paper flower production. For example, Lia Griffith's wax coated tape can simulate the texture of real flower petals through waterproof treatment, and a single roll can produce 20-30 paper flowers with a diameter of 10cm.

Mixed media art: The high reflectivity of metal tape is used by artists for collage creation. In the "Language of Light" exhibition at the Museum of Modern Art (MoMA) in New York, artists use 0.03mm thick copper foil tape to present molecular structure models through laser cutting technology.

In the field of commercial design

Brand packaging upgrade: The fast-moving consumer goods industry enhances the unboxing experience through customized decorative tape. Starbucks' 2024 Christmas limited edition packaging uses laser PET tape to secure cup covers, extending the interaction time during the unboxing process by 30% and increasing social media sharing rates by 45%.

Space decoration solution: In the field of architectural decoration, large-sized decorative tape (width 5-10cm) is used for wall color separation. IKEA's new product "Geometric Space" series in 2025 achieves "seamless wall art" through removable paper tape. A single roll can cover a wall area of 1.5 square meters, and the construction efficiency is 60% higher than traditional coatings.

Innovation in educational tools: STEAM educational institutions have introduced conductive tape (thickness 0.1mm, resistivity ≤ 1 Ω/cm) into circuit teaching. Students can complete simple circuit connections by sticking the tape, and the experimental success rate has increased from 65% in traditional soldering processes to 92%.

3、 Maintenance and Storage: Scientific Methods for Extending Material Life

environmental control

Temperature and humidity management: Tape should be stored in an environment of 15-25 ℃ and 40-60% RH. Experiments have shown that under the conditions of 35 ℃/80% RH, the viscosity of the adhesive tape decreases by 40% after 30 days, while PET tape will experience brittleness in an environment of -10 ℃.

Light protection: UV light can accelerate the aging of adhesive tape. Using a black dark bag for storage can extend the lifespan of the tape by 2-3 times. For example, metal tape that is not stored in a dark bag will experience a 60% decrease in glossiness after 6 months, while storage in a dark bag will only result in a 15% decrease in glossiness.

Usage Specifications

Surface pretreatment: Clean the surface dust before pasting (particles with a diameter greater than 5 μ m will cause 50% loss of adhesion). For smooth surfaces such as metal and glass, it is recommended to use isopropanol for wiping; For rough surfaces such as wood and fabric, sandpaper should be used to polish them to 600 grit.

Pasting technique: Using the "S-shaped" pasting method can reduce the generation of bubbles. Experimental data shows that the bubble rate of straight line pasting is 12%, while the "S-shaped" pasting can be reduced to 3%. For large-area pasting, it is recommended to use a pressure roller (pressure ≥ 2kg/cm ²) to remove air.

Long term maintenance

Layered storage: Multiple rolls of tape should be stacked vertically, with a spacing of ≥ 1cm between each roll to prevent deformation. Tests have shown that horizontal stacking can cause a curling rate of up to 15% at the edge of the tape, while vertical storage can be controlled within 3%.

Regular inspection: Check the adhesive tape adhesion every 3 months, which can be tested through the "finger pressure test" (if there is no rebound within 3 seconds after pressing, it is considered invalid). For the failed tape, a hair dryer can be used to heat it at low temperature (50-60 ℃) to restore some of the stickiness, but the effect can only be maintained for 24 hours.

Previous: Pink Washi Tape

Next: Washi Tape Stickers

2/F, No. 23, Um Yuan Xin Road, Wentang Community, Dongcheng Street, Dongguan City, Guangdong Province, China

+86 137-1733-9986 +86-0769-22299566